lfam printing service

COMING TO HAWAII

EXPANDING LOCAL MANUFACTURING CAPABILITIES

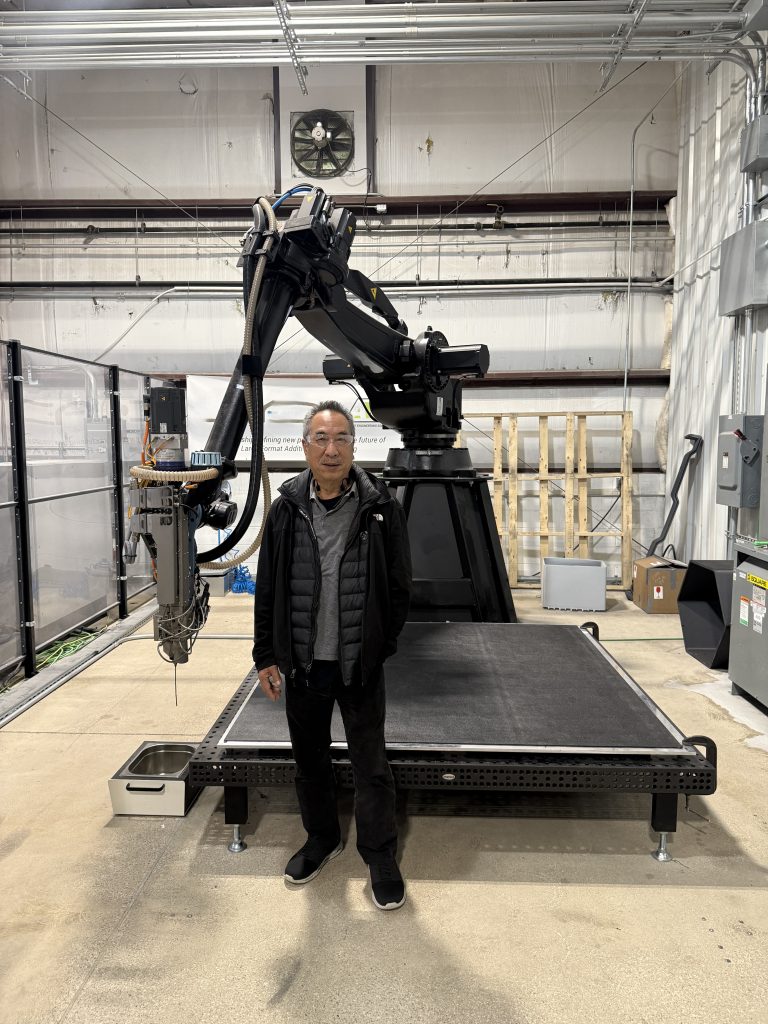

Large Format Additive Manufacturing (LFAM) is an established industrial technology that Min Plastics & Supply, Inc. is introducing to Hawaiʻi as part of our continued investment in local manufacturing. This capability expands what is possible for large, complex plastic parts and assemblies while supporting the unique demands of projects in the islands.

As a long standing plastics and fabrication partner, we approach new technologies with a practical mindset. LFAM is being integrated alongside our existing fabrication, machining, and material expertise to help address real world challenges facing Hawaiʻi industries.

Our focus is on strengthening local capability, improving responsiveness, and supporting innovation where it can add value across building, infrastructure, industrial, and public works projects.

Local investment. Practical innovation. Built for Hawaiʻi.

for real world large plastic parts

Large Format Additive Manufacturing (LFAM)

Large Format Additive Manufacturing (LFAM) enables the production of oversized plastic components without the limitations of traditional tooling. It is well suited for prototypes, fixtures, molds, and production parts where scale, speed, and design flexibility are required.

At Min Plastics and Supply, Inc., LFAM is used as a practical manufacturing method within an active fabrication environment. Printed components are supported by downstream machining and finishing capabilities to meet functional and dimensional requirements.

All LFAM parts are produced locally in Hawaiʻi, providing a dependable option for large or custom plastic components that need to move quickly from concept to finished part.

Built for real world applications. Produced with proven methods.

SIZE & COMPLEXITY BECOME your advantage

When Manual Fabrication Limits Progress

Producing large parts using traditional fabrication methods often leads to high tooling costs, long lead times, and limits on geometry or complexity. As parts grow in size, manufacturing becomes more labor intensive and harder to adjust.

Rising labor costs, shortages of skilled workers, and long lead time parts add further pressure. For Hawaiʻi based projects, shipping delays and logistics costs can make large or complex parts even more difficult to manage.

Large Format Additive Manufacturing offers an alternative for large parts that are constrained by traditional methods. By producing components directly from digital models, LFAM can reduce complexity, simplify assemblies, and support more flexible timelines.

An alternative worth considering when traditional fabrication creates barriers.

DESIGNED TO REDUCE COMPLEXITY AND LEAD TIME

LFAM Capabilities & Applications

Large Format Additive Manufacturing is an established industrial process that supports both prototype and production focused work for large plastic parts and assemblies. This approach enables complex components to be produced efficiently while maintaining structural integrity, dimensional stability, and design flexibility.

Across the manufacturing industry, LFAM is commonly applied when traditional fabrication methods introduce long lead times, high labor requirements, or practical limits on part complexity and assembly size.

Typical LFAM applications include:

• Large plastic parts and structural components

• Consolidated assemblies designed to reduce part count

• Complex geometries that are difficult to fabricate using traditional methods

• Fixtures, molds, patterns, and production tooling

• Parts intended for secondary machining and finishing

Printed components are often further refined through CNC machining to achieve tighter tolerances, improved surface finish, or integration into larger assemblies. Min Plastics is bringing this capability to Hawaiʻi as part of a broader investment in expanding local manufacturing options.

A practical manufacturing approach focused on reduced lead times, lower overall costs, and reliable part performance.

GUIDANCE FROM START TO FINISH

Our LFAM Process

1. Design Review and Feasibility

We begin by reviewing drawings, models, or existing parts to understand size, geometry, performance requirements, and application constraints. This step establishes how Large Format Additive Manufacturing (LFAM) may support project goals within real world conditions.

2. Design Preparation for LFAM

Once an application is identified, designs are prepared for large format additive manufacturing. This includes evaluating geometry, structural requirements, and considerations for downstream machining or assembly when required.

3. Large Format Additive Manufacturing

LFAM enables parts and assemblies to be produced directly from digital models. This process supports large scale components, complex geometry, and consolidated assemblies without traditional tooling, expanding available manufacturing options.

4. Refinement and Finishing

Printed components may be further refined through machining, surfacing, drilling, or other finishing operations to meet dimensional, functional, or integration requirements.

5. Delivery and Integration

Parts are prepared for delivery, installation, or integration into larger systems. Clear communication throughout the process helps align expectations as projects move forward.

A structured approach designed to reduce risk, lead time, and complexity as this capability is introduced.

EXPERIENCE ROOTED IN REAL WORLD FABRICATION

Why Customers Choose Min Plastics

Min Plastics and Supply, Inc. is built on decades of experience working with plastics and understanding how materials behave in real world fabrication. We approach Large Format Additive Manufacturing as part of a broader manufacturing toolkit, not as a one size fits all solution.

As we invest in bringing LFAM technology to Hawaiʻi, our team applies the same practical evaluation and fabrication mindset that guides all of our work. This includes helping customers understand where new manufacturing capabilities may support project goals alongside established methods.

As a locally based manufacturer in Hawaiʻi, we provide responsive support and hands on collaboration. We work with teams across HVAC, infrastructure, marine, industrial, and public works to help bring solutions to market efficiently and responsibly.

• Long standing plastics and fabrication experience

• Local Hawaiʻi based production and responsive staff

• Practical evaluation of emerging manufacturing technologies

• Reliable execution through established fabrication and machining capabilities

A trusted local partner committed to expanding manufacturing options in Hawaiʻi.

REAL WORLD LFAM APPLICATIONS

LFAM Parts & Assemblies in Practice

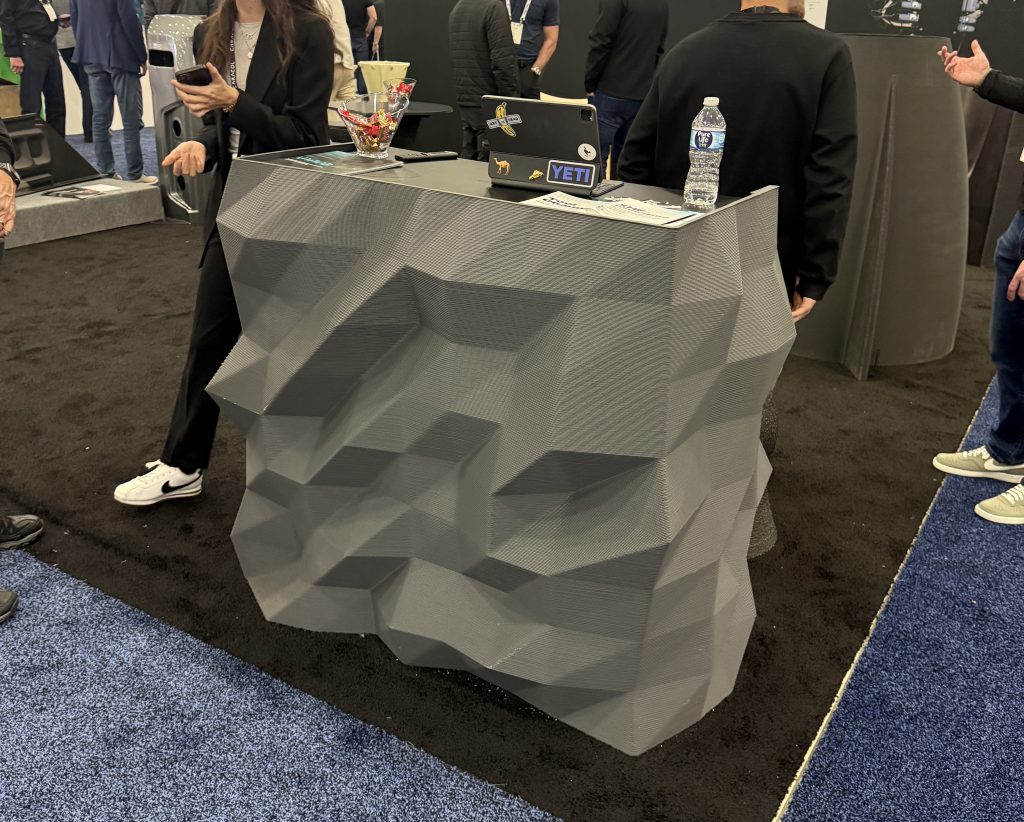

Large Format Additive Manufacturing (LFAM) is an established technology used by fabricators and manufacturers to address challenges associated with large and complex parts and assemblies. The examples shown represent common LFAM use cases identified across the manufacturing industry.

These examples illustrate how LFAM has been applied to large plastic parts and assemblies at different stages, including as printed components, parts prepared for secondary machining, and finished assemblies ready for integration. They are provided to demonstrate the types of applications where LFAM has proven effective.

Illustrative examples of LFAM applications identified across the manufacturing industry.

LOCAL SUPPORT AND NEXT STEPS

Ready to Discuss Your Project?

If you are exploring new manufacturing approaches for large or complex plastic parts, our team is available to review your requirements and discuss potential options. As LFAM is introduced, we continue to support projects through established fabrication and machining capabilities.

Our focus is on clear communication, practical guidance, and dependable local support.

Fill out the contact form below to inquire 🙂

Supporting Hawaiʻi projects with local expertise and long term commitment.