cnc routing service

precision services. finished solutions.

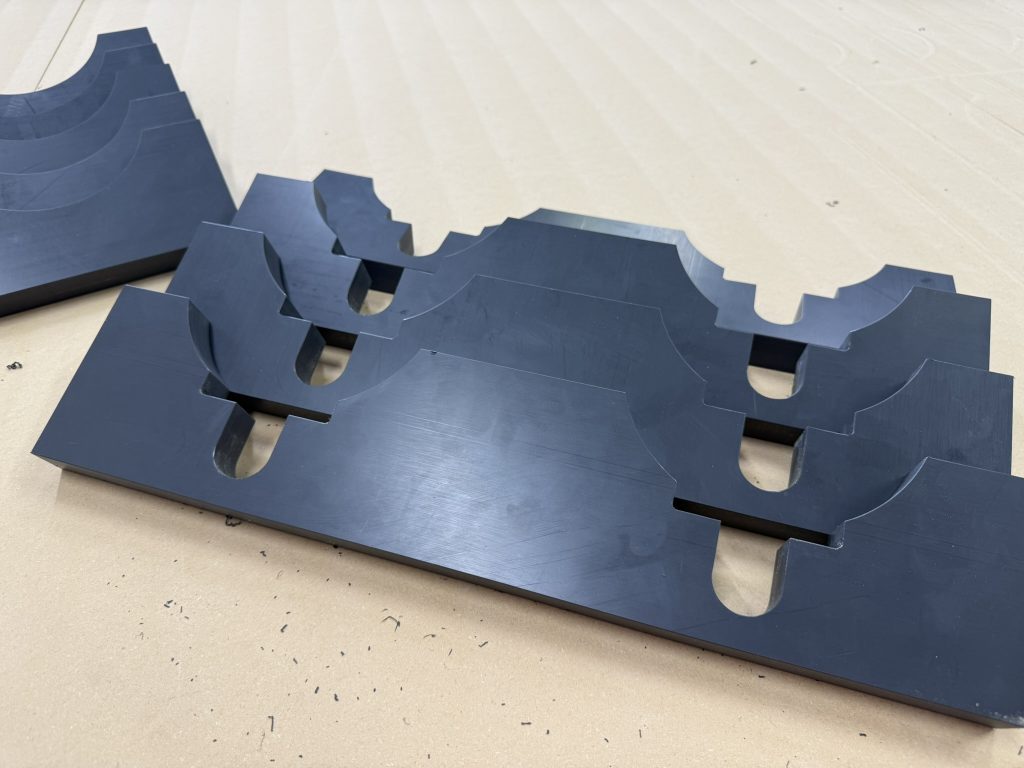

Precision Cutting for Plastics & Sheet Materials in Hawaii

When projects require accurate, repeatable cutting of plastics and sheet materials, Min Plastics & Supply, Inc. provides CNC routing services designed for real-world applications, from one-off custom parts to repeat production runs. Our precision plastic cutting services help you avoid delays, tight tolerances issues, and costly rework so your parts fit and perform as intended

Whether you’re fabricating components for industrial assemblies, architectural installations, signage, or custom builds, we specialize in CNC routing and plastic fabrication with clean edges and reliable turnaround right here in Hawaiʻi

Not sure if CNC routing is the right solution?

Our team reviews every project for material selection, tolerances, and application fit—so you get parts that perform as expected, without surprises.

Accurately parts, ready for your application.

What CNC Routing Helps You Solve

CNC routing is ideal when projects demand consistency, accuracy, and control that hand cutting cannot provide. Our services help customers solve challenges such as:

Complex shapes and patterns

Oversized panels and non-standard thicknesses

Repeatable parts that must align across multiple panels

Tight timelines and local installation constraints

Materials that require experience to machine correctly

We focus on how parts will perform after they leave the table — during installation, use, and long-term service.

precision - accuracy - consistency

CNC ROUTING CAPABILITIES

Our CNC routing services support both prototype and production work using industry-standard CNC routing techniques tailored for plastics:

Precision sheet cutting up to 7′ x 10′

Lettering and decorative parts routing

Cut to your template, supplied pattern, existing part

Draft angles for mold release

Edge profiling, chamfering, threading

Multi-panel alignment for large assemblies

We work from CAD files or hand sketches and apply material-specific machining techniques to deliver consistent, clean cuts, with high-quality results.

CAD 2D File Formats: .dxf, .eps, .ai, .svg, .pdf

Precision-Routed Sheets and Parts, Ready to Install

How Our CNC Routing Process Works

Materials We CNC Route

Plastics

HDPE

UHMW

ABS

PETG

Acrylic

Polycarbonate

Expanded PVC

Additional Sheet Materials

Plywood

MDF

Aluminum (non-ferrous)

Foam & rigid foam boards

Material selection and cutting strategy are matched to your application to ensure performance, durability, and clean results.

Each material is routed using industry proven methods to ensure clean and reliable results.

Expertise That Shows in Every Cut

Why Min Plastics for CNC Routing

Customers choose Min Plastics because CNC routing here is backed by material knowledge and fabrication experience, not just machine time.

Expertise in plastics and engineered sheet materials

Large-format 7′ x 10′ routing capability

Clean cuts with minimal post-processing

Local inventory and mainland sourcing options

Experience with architectural, museum, and industrial applications

With decades of fabrication experience, we understand how CNC-routed parts integrate into finished assemblies, molds, enclosures, and displays.

Precision and Clarity. Without the Guesswork.

GUIDANCE FROM START TO FINISH

From Design to Delivery

Whether you’re supplying detailed CAD files or early-stage concepts, our team works closely with you to determine the right material, routing approach, and production timeline. We support projects from initial prototype through repeat production, with a focus on accuracy, reliability, and practical fabrication.

Defined workflows and repeatable methods, built for production.

fRIENDLY, LOCAL SUPPORT

Ready to move your project forward?

If you need CNC routing for plastics or sheet materials for oversized, custom, or time-sensitive projects, our team is here to help you move forward with confidence.

We work from your drawings or existing parts and deliver accurate, repeatable results, without delays or guesswork.

No obligation. Quick review. Find Your Next Step.