ServiceS

precision services. finished solutions.

Engineered Plastic Solutions for Hawaii

From material sourcing to finished fabrication, Min Plastics & Supply, Inc. provides engineered plastic services built to perform in real-world conditions.

When quality, durability, and visual clarity matter — especially in Hawaiʻi — we help move projects forward with confidence.

plastics shouldn’t be guesswork

When Plastics Aren’t Your Expertise

Complex projects demand performance and results, not guesswork.

For many teams, plastics are unfamiliar territory.

What material is right for the application?

How thick does it need to be?

Will it hold up in real-world use?

How should it be designed, cut, assembled, and installed?

Without the right knowledge, experience, or partner, plastics can feel uncertain — forcing teams to rely on assumptions, trial and error, or multiple vendors to piece solutions together.

That uncertainty slows projects down and increases risk.

A knowledgeable partner who demystifies plastics.

What We Handle So You Don’t Have To

That’s why we’ve organized our services around how projects actually get done — from sourcing, cutting, to fabrication, and installation quality.

MATERIALS SOURCING MADE SIMPLE

Materials & Procurement

Engineered plastic sourcing tailored to Hawaiʻi — from specific thicknesses and sheet sizes to specialty grades, colors, coatings, and logistics.

Whether materials come from our in-house inventory or trusted manufacturing partners nationwide, we help ensure the right material arrives on schedule and ready for fabrication.

No delays. No surprises. No unnecessary handoffs.

If we don’t have it, we’ll find it.

Trusted by commercial, institutional, and public-sector clients across Hawaiʻi.

We’ll help you choose the right material and coordinate delivery.

Accurately cut pieces, ready for your application.

Cut-2-Size

When projects don’t require full fabrication but still demand precision, our cut-to-size service delivers clean, accurate cuts using professional equipment — without the waste or guesswork.

We process engineered plastics to your specified dimensions using CNC panel saws and routing equipment, ensuring consistency, squareness, and reliable results.

Guidance at every step — no guesswork required.

Sheets and parts sized to your exact needs.

precision cutting for accuracy & consistency

CNC Routing Service

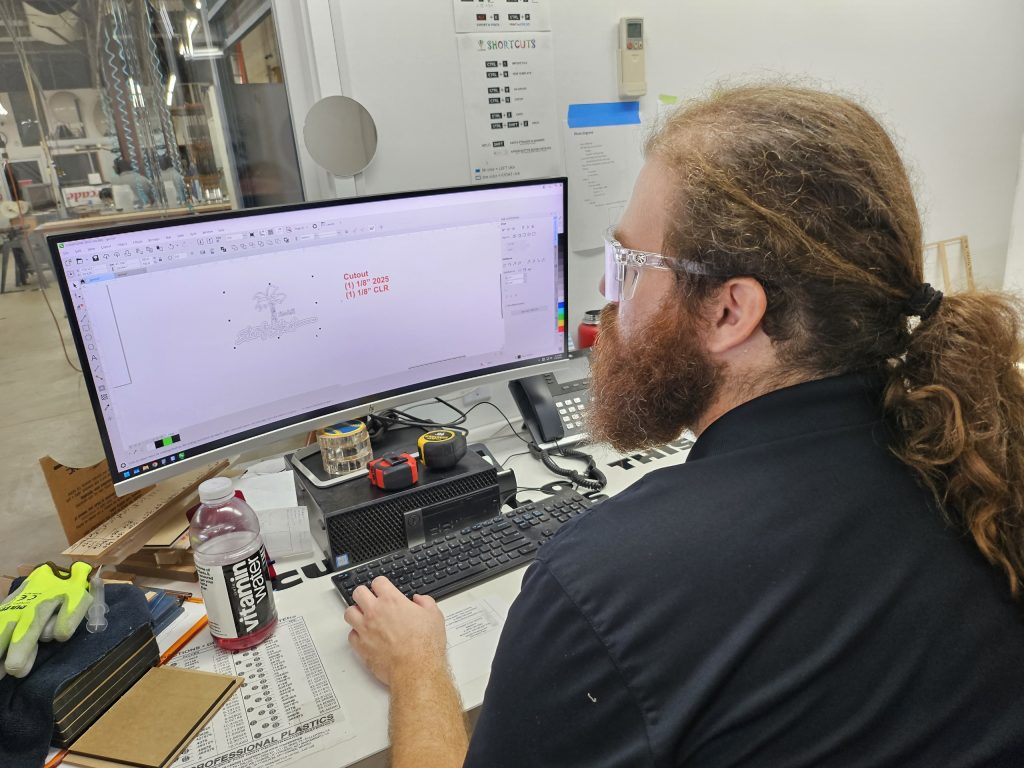

Accurate, repeatable CNC routing for engineered plastics used in high-visibility, high-performance applications.

Our CNC routing services support commercial and institutional projects where clean edges, tight tolerances, and consistency are critical. From single components to large-format production, each part is cut with precision and care.

Designed to fit, assemble, and perform as intended.

Available for public, residential, commercial, institutional, and island timeline projects.

We’ll guide you to the right material and cut for your application.

detailed and refined branding

Laser Cutting & Engraving Service

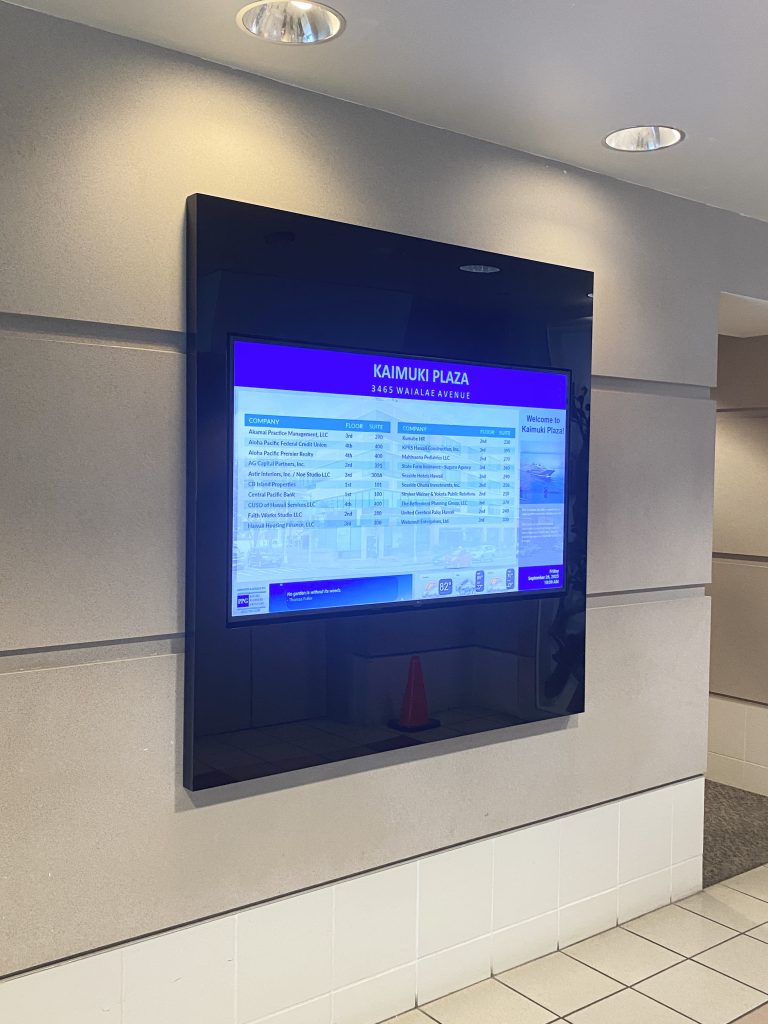

Crisp cutting, polished acrylic edges, and precise engraving for signage, branding, displays, and detailed components.

Our laser cutting and engraving services are used in commercial, institutional, and public environments where detail, clarity, and consistency matter. From single pieces to repeatable production, each project is executed with control and care.

Designed to integrate seamlessly into finished spaces.

Refined detail, without compromise.

Common applications include: cut acrylic parts, wayfinding, donor recognition, branded elements, display components, and labels.

Precise detail and clarity, not guesswork.

Custom-built to perform and endure.

Fabrication & Assembly

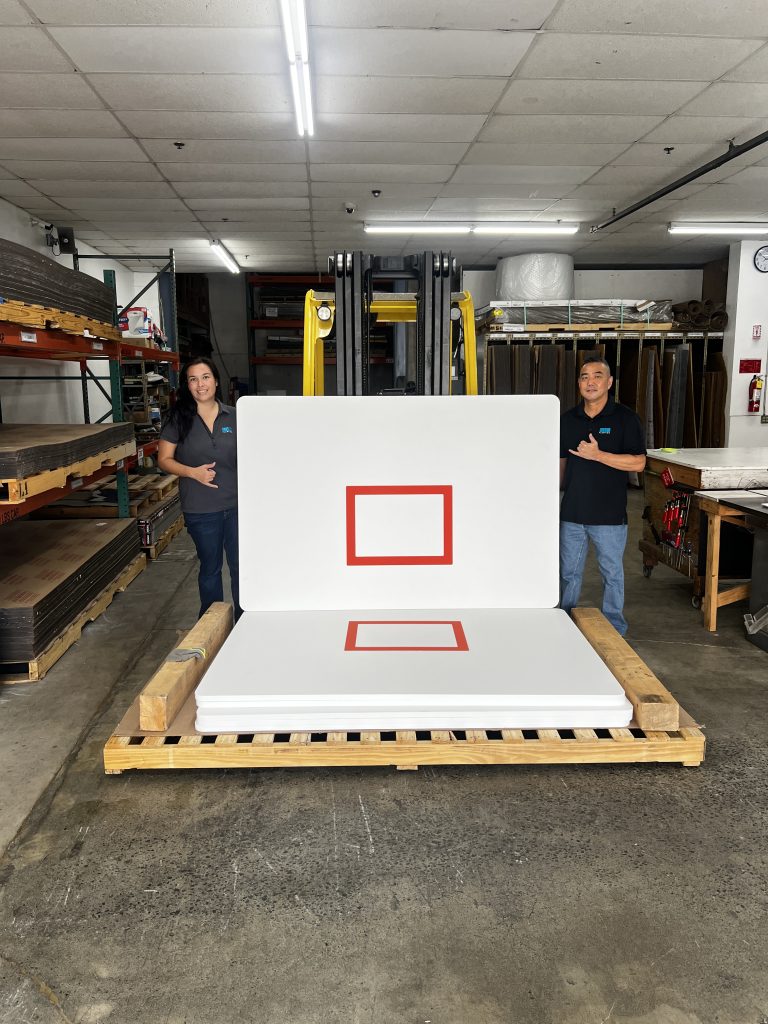

Custom fabrication and assembly for large-scale plastic components and finished installations.

Designed, built, and assembled using engineered plastics to perform in real-world environments — and to hold up over time.

More than parts. Complete solutions.

Clear recommendations based on how your project will be used.

From cut parts to finished assemblies.

built on experience. defined by quality

Our Approach

At Min Plastics & Supply, Inc., we specialize in engineered plastics and professional fabrication for projects where quality matters.

We work with materials like acrylic, polycarbonate, polyethylene, UHMW, ABS, polypropylene, and specialty engineered plastics — selected for long-term performance and appearance.

With decades of experience and in-house CNC, laser, and fabrication capabilities, we guide each project from concept through completion with clarity and care.

We help you choose the right material, thickness, and approach.

a SIMPLE, PROVEN APPROACH

How It Works

A clear, guided process that takes the guesswork out of fabrication. We make it easy to move from idea to finished solution.

- Define the Need – We review your drawings, requirements, and performance goals to understand what the project needs to do — and where it will live.

Select & Fabricate – Materials are selected or sourced, then fabricated with precision using CNC routing, laser cutting, and professional assembly to meet your timeline.

Deliver with Confidence – Components or complete assemblies are delivered ready for installation, integration, or pickup — built to perform as intended.A clear, guided process that takes the guesswork out of fabrication.

Practical guidance for unfamiliar materials.

We’ll help define requirements and next steps.

Where Our Work Lives

Min Plastics & Supply, Inc. supports projects across environments where durability, precision, and appearance all matter:

Commercial interiors and exteriors

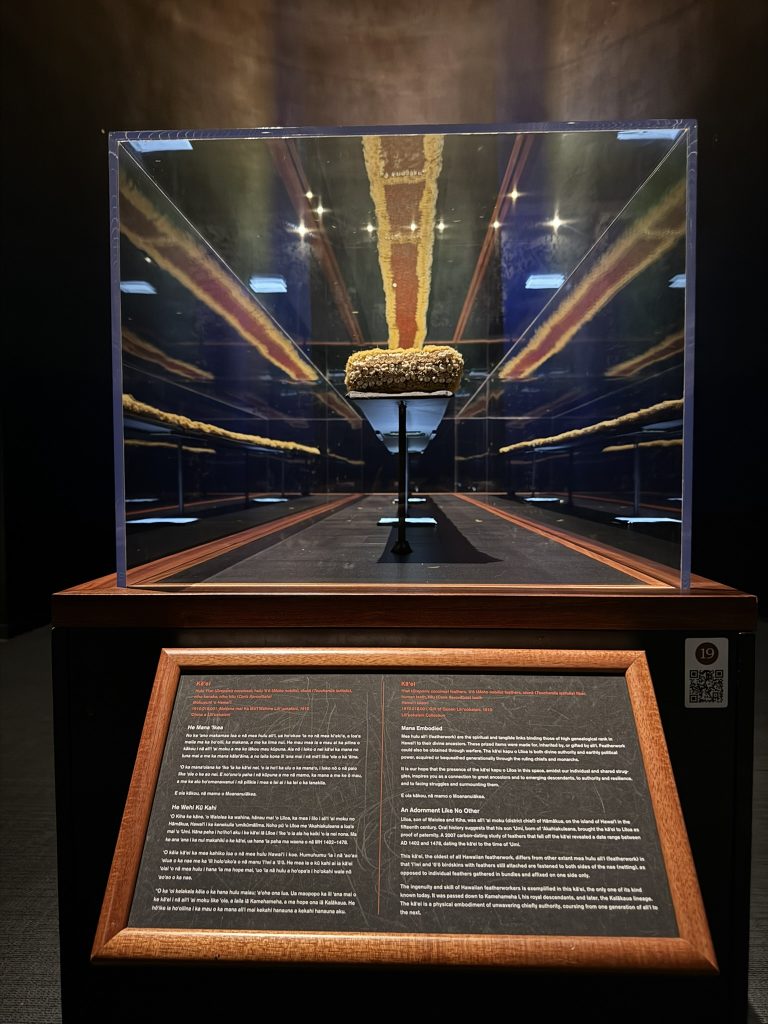

Museums and cultural institutions

Hospitality and public spaces

Exhibits, displays, and architectural installations

From high-traffic public spaces to museum-quality displays, our work is designed to perform — and to be seen.

Trusted by designers, facilities teams, and commercial builders across Hawaiʻi

fRIENDLY, LOCAL SUPPORT

Ready to move your project forward?

Whether you need precision cutting, custom fabrication, or help sourcing the right material, the local team at Min Plastics & Supply, Inc. is here to help.

From first questions to finished solutions, we’ll guide your project with clarity, care, and realistic timelines.

A knowledgeable partner who demystifies plastics.

Supporting the public, commercial, and Hawaiʻi timelines.