custom order

SOLUTIONS BEYOND STANDARD STOCK

Custom Orders and Special Sourcing

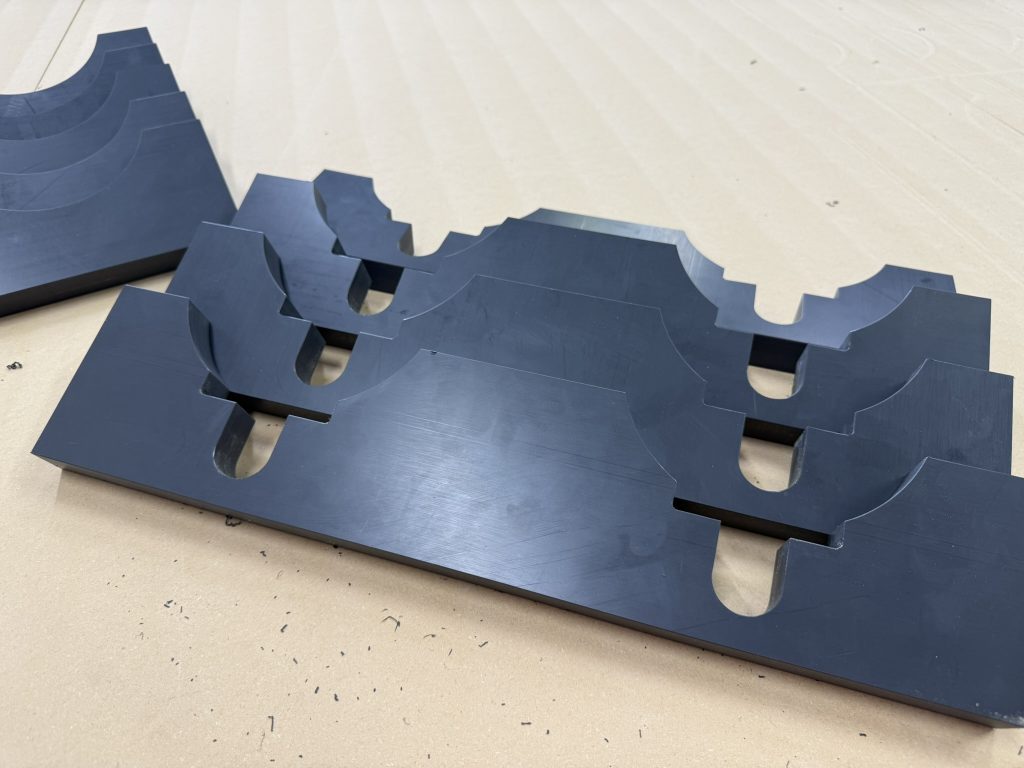

Not every project fits neatly into standard sizes or off the shelf materials. Min Plastics supports custom orders and special sourcing to help customers get the right material, size, or fabrication approach for their application.

Whether you are working from drawings, specifications, or a specific performance requirement, our team helps navigate options and lead times to support real world project needs.

Guidance you can rely on when standard options fall short.

WHEN CUSTOM ORDERS MAKE SENSE

Projects That Go Beyond Standard Materials

Custom orders are often used when projects require materials, sizes, or properties that are not readily available from stocked inventory.

Common reasons customers request custom orders include:

• Non standard sheet sizes or thicknesses

• Specialty plastics or engineered materials

• Specific color, finish, or performance requirements

• Large format or oversized components

• Projects with unique environmental or durability needs

This approach supports both one time project requirements and repeat production planning.

We help clarify when a custom approach adds real value to your project.

WHAT WE CAN SOURCE OR SUPPORT

Types of Custom Orders We Handle

Min Plastics supports a wide range of custom material and fabrication related requests, including:

- PVC Type I & II – Gray / White / Black

- Polygal Twin Wall System

- Ballistic Rated Laminated Polycarbonate – UL 752 Level 6

- Delrin

- Acetal

- UHMW-PE

Non-Stocked Thicknesses or Coatings

- Up to 6″ thick – Material Dependent

- Scratch/Abrasion Resistant Coated

- Extra Long Term UV resistant

- Impact Modified

Custom Sizes and Formats

- Oversized sheets & Extra Long Lengths >10′

- Cut to Size Blanks – As Available

- Spooled Material

A PRACTICAL APPROACH TO CUSTOM REQUESTS

How Custom Orders Are Evaluated

Custom orders are reviewed with a focus on practicality, lead time, and application fit. Our team works with you to understand performance requirements, budget considerations, and scheduling needs.

This collaborative approach helps ensure the solution selected supports the project as intended without unnecessary complexity.

Decisions informed by application requirements and real world use.

WHAT TO EXPECT

Lead Times and Planning

Custom orders may require additional lead time depending on material availability, sourcing requirements, or fabrication complexity.

We help set realistic expectations by communicating:

• Estimated lead times

• Minimum order quantities when applicable

• Material availability and alternatives

• Processing or fabrication considerations

Advance planning helps reduce risk and keep projects aligned with schedule.

Clear communication around lead times, availability, and planning.

LOCAL SUPPORT AND RESPONSIVE COMMUNICATION

A Local Partner for Custom Solutions

As a locally based supplier and fabricator in Hawaiʻi, Min Plastics provides responsive support throughout the custom order process. We work closely with customers across construction, industrial, marine, and public works projects to help bring solutions to market efficiently.

Local expertise. Practical solutions. Dependable support.

Local support backed by material knowledge and fabrication experience.

READY TO GET STARTED

Let’s Talk About Your Requirements

If your project requires materials or sizes beyond standard inventory, our team is available to review your requirements and discuss available options.

Straightforward conversations focused on practical outcomes.